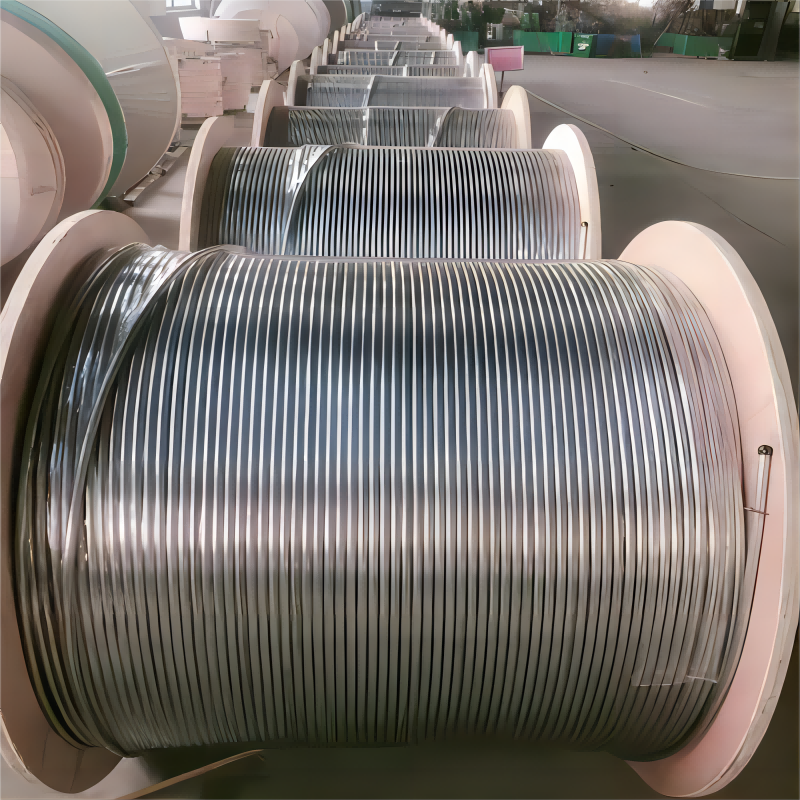

| Katrangan | Seamless Stainless Steel Coil Tubing | ||

| Bahan & Standar & Ukuran | Bahan: 201,202,301,304,304L,310S,316,316L,321,347 Standar: ASTM (ASME) SA / A312 / A213 / A269 , DIN, JIS, EN | ||

| Diameter metu:Φ6mm-25mmKetebalan Tembok:Φ0.7mm-2.11mm Toleransi: OD: ± 0.08mm, WT: ± 10% | |||

| dawa | Miturut macem-macem ukuran, dawa kumparan siji ing 500 meter kabeh tabung coil ora titik gandheng | ||

| Perawatan lumahing | Pickling Utawa Polish Annealed | ||

| Teknis | Dingin rolling pisanan, banjur kadhemen digambar coil | ||

| Jinis Pangiriman | alus | ||

| Jinis | Seamless lan Welde | ||

| Aplikasi | Tabung coil stainless steel digunakake akeh ing Pengeboran Minyak, Kimia, Industri Manufaktur Kapal Uap, Pertukaran Panas lan Industri Kimia Kondensor Pendingin, Pipa Gas dll | ||

Kelas Stainless Steel

| Komposisi kimia | Komposisi Bahan | 201 | 304L | 304 | 316 | 316L |

| C | ≤0.15 | ≤0.03 | ≤0,08 | ≤0,08 | ≤0.03 | |

| Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

| Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤2.00 | |

| P | ≤0.06 | ≤0,035 | ≤0,035 | ≤0,035 | ≤0,035 | |

| S | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | |

| Cr | 16-18 | 18-20 | 18-20 | 16-18 | 16-18 | |

| Ni | 3.5-5.5 | 8-12 | 8-10.5 | 10-14 | 10-14 | |

| Mo | 2.0-3.0 | 2.0-3.0 | ||||

| Properti Mekanik | Materi Item | 201 | 304L | 304 | 316 | |

| Kekuwatan Tensile | ≥535 | ≥520 | ≥520 | ≥520 | ||

| Kekuwatan Ngasilake | ≥245 | ≥205 | ≥205 | ≥205 | ||

| Ekstensi | ≥30% | ≥40% | ≥35% | ≥35% | ||

| Kekerasan (HV) | <253 | <200 | <200 | <200 | ||

Wektu kirim: Jan-20-2023