Rega 2507 Stainless Steel Coil Tubing

Komposisi Duplex Stainless Steel

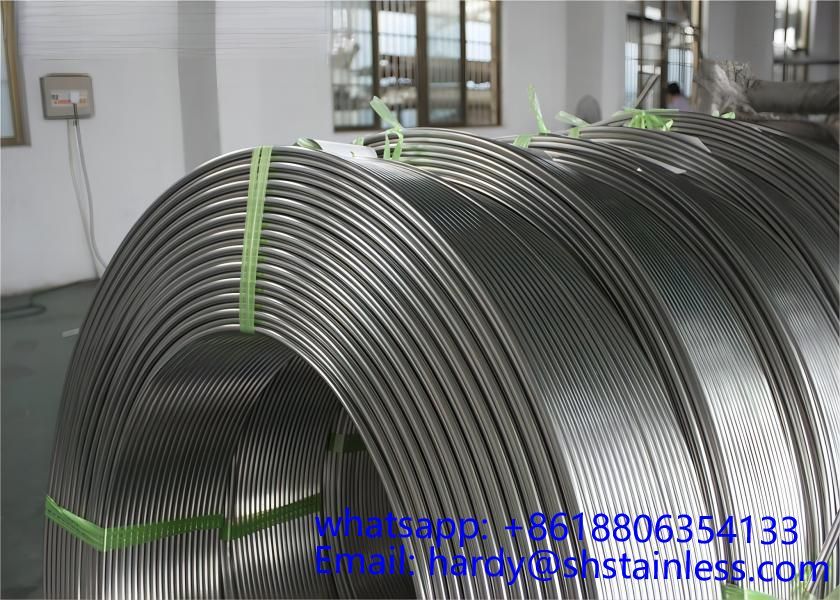

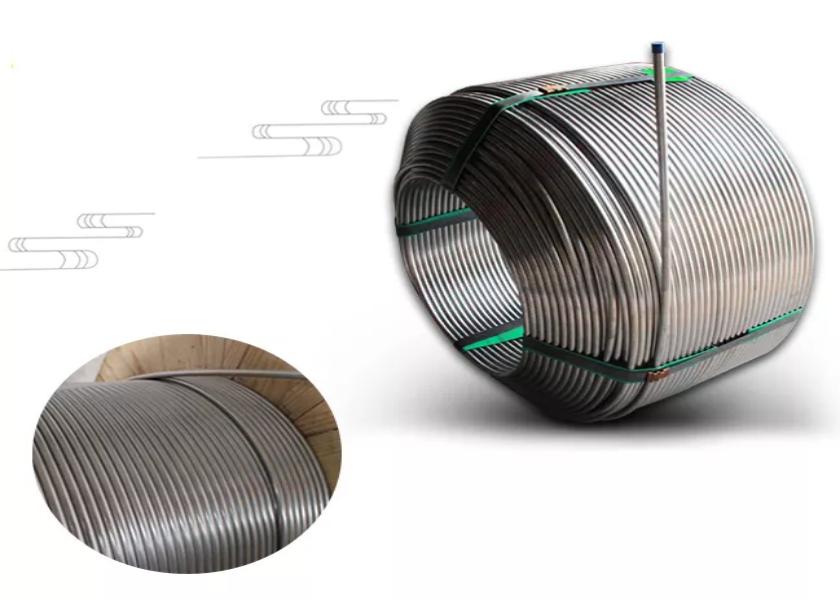

Super Duplex 2507 kasedhiya ing macem-macem formulir kayata Lurus, Coiled, Seamless, Jahitan gandheng, redrawn kadhemen lan anil.Aplikasi khas ing garis kontrol Subsea, Offshore, Fire-fighting sistem, Injeksi & ballast sistem banyu, Heat exchanger etc. ngendi industri utamané nggunakake Kelas iki industri Processing kimia lan industri petroleum.

S32750 / S32760 Super Duplex Komposisi Kimia

| S32750 / S32760 | C | N | P | Si | Mn | Mo | Ni | Cr | S | Liyane |

| 0.030 | 0.24/0.32 | 0.035 | 0.80 | 1.20 | 3.0/5.0 | 6.00 / 8.00 | 24.0/26.0 | 0.020 | Cu: 0,50 |

Super Duplex Steel S32750 / S32760 Sifat Mekanik

| S32750 / S32760 | Kapadhetan | Titik Lebur | Kekuwatan Ngasilake (0,2% Offset) | Kekuwatan Tensile | Elongation |

| 7,8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000, MPa – 550 | Psi – 116000, MPa – 800 | 15 % |

Super Duplex 2507 padha karo

Kelas sing padha kanggo S32750 / S32760 Super Duplex Stainless Steel

| Super Duplex 2507 Spesifikasi Standar | UNS | WERKSTOFF NR. |

| Super Duplex S32750 | S32750 | 1.4410 |

| Super Duplex S32760 | S32760 | 1.4410 |

Super Duplex 2507 (UNS S32750)

Komposisi%

| C Karbon | Mn Mangan | P Fosfor | S belerang | Si silikon | Ni nikel | Cr Kromium | Mo Molybdenum | N Nitrogen | Cu Tembaga |

| 0,030 maks | 1.20 maks | 0,035 maks | 0,020 maks | 0,80 maks | 6.0–8.0 | 24.0–26.0 | 3.0–5.0 | 0.24–0.32 | 0,50 maks |

Toleransi dimensi

| OD | OD Toleransi | Toleransi Tembok |

| ≤ .500” | ± .005” | ± 15% |

| 0.500"–1.500" ora kalebu | ± .005” | ± 10% |

Sifat Mekanik

| Kekuwatan Ngasilake: | 80 ksi min |

| Kekuwatan Tensile | 116 ksi min |

| Elongation (min 2") | 15% |

| Kekerasan (Skala Rockwell C) | 32 HRC maks |

Aplikasi Industri

Proses Kimia

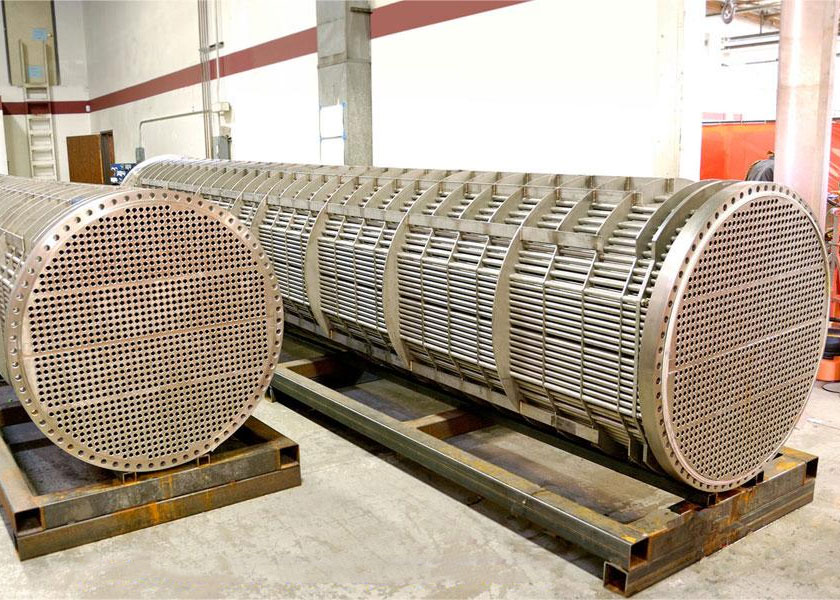

Super Duplex 2507 dirancang kanggo aplikasi sing mbutuhake kekuwatan lan ketahanan korosi sing luar biasa, sing ditemokake ing peralatan proses kimia, petrokimia, lan banyu laut.Paduan kasebut digunakake ing proses penguapan uyah, penukar panas, lan lingkungan asam hidroklorat.

Foto Pabrik

Inspeksi

Pengiriman & Packing

Laporan Tes