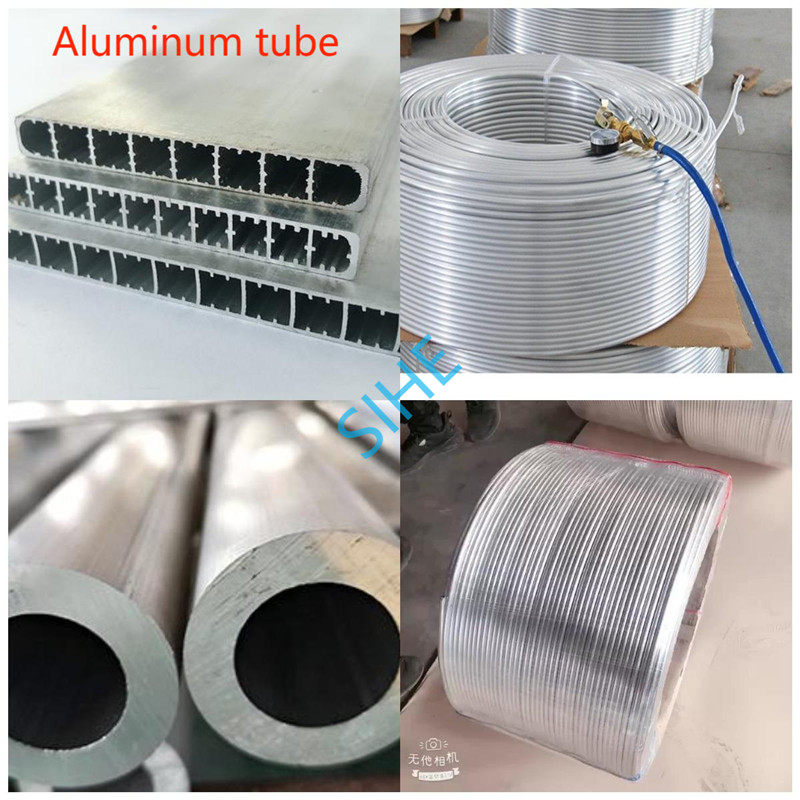

1060 aluminium coiled tabung

ASTM B210 1060 Aluminium coil tube kanggo Evaporator

1060 aluminium alloy minangka paduan basis aluminium ing kulawarga tempa "komersial murni" (seri 1000 utawa 1xxx).Iku dhasar banget padha karo 1050 aluminium alloy, karo prabédan teka mudhun kanggo 0,1% aluminium dening bobot.

Tabung aluminium kanggo industri HVAC&R.lumahing tabung coiled Gamelan, ora pori, ora nyandhang, lan nitrogen wis maintained.tabung aluminium utamané cocog kanggo produksi dawa mlaku kanggo aplikasi industri.Utamane digunakake ing AC, freezer, kulkas, Kondensor, intercooler, evaporator, gerakan angin anget, pipa AC, radiator mobil, lsp.

1.Alloy: ASTM B241 1050/1060/1070

2. Temperamen: O/H12/H14/H16/H22/H24/H26/H112/F

3. Kekandelan: 0.7mm--1.5mm

4. Diameter: miturut syarat customer

5. Toleransi: +/- 0,05mm

6. Aplikasi: AC, kulkas, evaporator roll-bond, penukar panas, gas oven, kondensor, lan intercooler lan liya-liyane.

7. Paket: Palet kayu utawa kothak sing cocok kanggo transportasi laut jarak adoh, bisa disesuaikan karo klien.

Spesifikasi

| Komposisi Kimia Aluminium A1050 | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | liyane |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| Komposisi Kimia Aluminium A1060 | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | liyane |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| Komposisi Kimia Aluminium A1070 | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | liyane |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| Sifat Fisik 1050 1060 1070 pipa tabung aluminium | ||||||

| Paduan | Temper | Ketebalan tembok | Asil Tes suhu kamar | |||

| Kekuwatan Tegangan/MPa | Kekuwatan Ngasilake / MPa | Elongation/% | ||||

| A50 mm | A | |||||

| Ora kurang saka | ||||||

| 1050 | O, H111 | Kabeh | 60 ~ 100 | 20 | 25 | 23 |

| H112 | Kabeh | 60 | 20 | 25 | 23 | |

| F | Kabeh | - | - | - | - | |

| 1060 | O | Kabeh | 60 ~ 95 | 15 | 25 | 22 |

| H112 | Kabeh | 60 | - | 25 | 22 | |

| 1070 | O | Kabeh | 60 ~ 95 | - | 25 | 22 |

| H112 | Kabeh | 60 | 20 | 25 | 22 | |

jaminan kualitas

1) katon lumahing: lumahing resik warata ora wutuh, ngeruk, lenga reged utawa oksidasi.

2) pinggiran nglereni: pinggiran nglereni rapi ora burrs.

3) Goal kualitas: tingkat kualitas inspeksi produk frist yaiku 98%. Kepuasan pelanggan kanthi 95%. Materi: A1050, A1060, A1070, A3003, lan liya-liyane

| Komposisi Kimia Aluminium A1050 | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | liyane |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| Komposisi Kimia Aluminium A1060 | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | liyane |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| Komposisi Kimia Aluminium A1070n | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | liyane |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| Komposisi Kimia Aluminium A3003 | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Liyane Single | |

| liyane | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

| Paduan | Temper | Spesifikasi | |||

| Ketebalan (mm) | Dhiameter (mm) | Kekuwatan tensile | Kekerasan | ||

| 7075 7005 (tabung) | T5, T6, T9 | > 0.5 | 5.0-80 | > 310 Mpa | > 140 |

| 6061 6063(profil) | T5, T6 | > 1.6 | 10-180 | > 572 Mpa | HB90-110 |

| Dawane: < 6 Meter | |||||

| TEMPER | Ketebalan (mm) | KEKUATAN TENSI | ELONGATION% | Standar |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB / T3190-1996 |

Produk aluminium